I. The Underlying Purification Mechanism

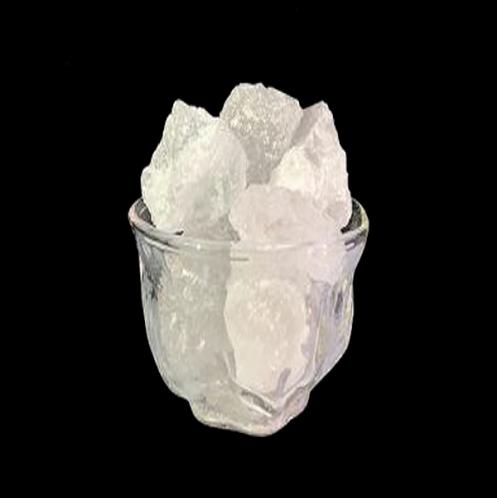

Both types of alum function based on the ability of aluminum ions. Once dissolved in water, they release aluminum ions ( ) which then engage in a hydrolysis reaction: . The resulting aluminum hydroxide colloid is like a tiny magnet for impurities. It can latch onto suspended solids such as silt, particulate matter, and even some organic substances, effectively clearing the water and giving it a more transparent appearance.

II. Safety Perspectives

- Potassium Alum: In the process of water treatment, potassium alum proves to be relatively benign. The potassium ions it liberates are generally stable and pose minimal threat to human well-being. Provided that the proper dosage is adhered to, potassium ions do not tend to accumulate within the body and cause harm. Its long-standing use in various applications also lends credence to its safety profile.

- Ammonium Alum: Attention must be paid to the ammonium ions ( ) from ammonium alum. Under specific circumstances, these ions can transform into ammonia gas ( ). If this occurs during water storage or usage post-purification, it can lead to an unpleasant, pungent odor that mars the sensory quality of the water. More concerningly, inhalation of excessive amounts of ammonia can irritate the respiratory tract and potentially damage the lungs. This risk becomes especially pronounced in enclosed or poorly ventilated settings.

III. Efficiency in Purifying Water

- Colloid Formation Rate: There isn’t a significant disparity between potassium alum and ammonium alum in terms of how quickly they form the all-important aluminum hydroxide colloid. Given identical water conditions, temperature, and dosing regimens, both substances can initiate the production of the colloidal particles with adsorption capabilities at a comparable pace, swiftly populating the water with these impurity-trapping agents.

- Colloid Stability: Here, potassium alum shows a bit of an edge. The aluminum hydroxide colloid formed by potassium alum tends to stay dispersed in the water for a longer duration. It resists clumping together and settling, which means it can continue to attract and bind to any new or remaining impurities. In contrast, ammonium alum-generated colloid may sometimes succumb to premature flocculation due to minor changes in water chemistry, like pH fluctuations or gentle water movement, reducing its overall effectiveness.

IV. Applicable Situations

- For Small-Scale Water Supply Systems: In scenarios like small rural water supply setups or basic water stations in remote regions, if the water source is relatively consistent and there’s ample open space for water storage along with decent ventilation, ammonium alum could be a viable option. It often comes with a lower cost tag and can meet the rudimentary water purification demands. By implementing proper water storage designs, the issue of ammonia volatilization can be managed to some extent.

- For General Urban and High-Quality Drinking Water Needs: In most urban water supply networks, household water purifiers, and any application where top-notch drinking water quality is non-negotiable, potassium alum takes the lead. Its combination of safety and reliable colloid stability makes it the go-to choice. It ensures that every drop of water that reaches consumers is not only clear but also safe to drink.

In conclusion, while both potassium alum and ammonium alum have their roles in water purification, potassium alum’s advantages in safety and colloid stability make it a more preferable option for a broader range of applications. However, a careful evaluation of factors such as the water supply scale, source quality, and the surrounding environment is essential to make the most appropriate choice.